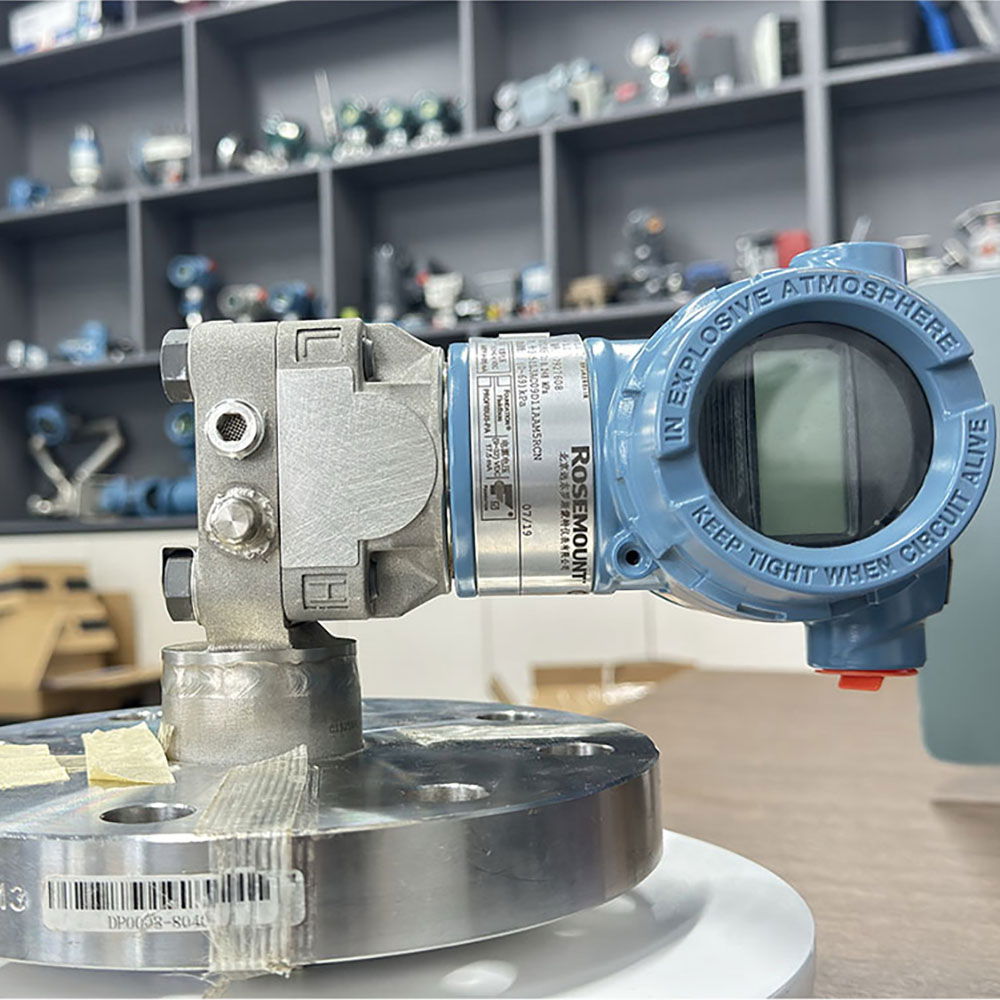

Rosemount 3051L liquid level transmitter

Rosemount™ 3051L Level Transmitter

Direct mount or use a Tuned-System™ assembly that optimizes performance and reduces temperature effects by 10-20% for improved response time by over 80% versus traditional installations. Built-in diagnostics detect electrical loop issues and alert you to corrosion, water in the housing, or unstable power supply. Available with a graphical, back-lit display, Bluetooth® connectivity, Level specific configuration and enhanced software capabilities designed to access the data you need faster than ever before.

Rosemount 3051L is a fully-integrated level solution, which offers field-proven reliability.

This transmitter is safety certified, and makes possible Tuned-System™ assembly or direct mounting.

This helps reduce the temperature effects by 10-12%.

The response time is improved by more than 80% compared to that of traditional installations.

This helps in optimizing the overall performance.

Features

Tuned-System Level assembly and direct mounting produce optimal performance for level applications

Application specific configuration allows you to transform your pressure transmitter into a level transmitter with volume calculations

Complete level assemblies are leak-tested and calibrated to reduce leak points up to 70% and simplify installation

10-year installed stability and 150:1 rangedown produce reliable measurements and wide application flexibility

Bluetooth® wireless connectivity unlocks a far simpler process to perform maintenance and service tasks without the need for a physical connection or separate configuration tool

The graphical, back-lit display allows for easy operation in 8 different languages in all lighting conditions

Loop Integrity and Plugged Impulse Line diagnostics detect electrical loop issues and plugged impulse piping before it impacts the quality of the process for increased safety and reduced downtime

Quick service buttons offer built-in configuration buttons for streamlined commissioning

SIL 2/3 certified to IEC 61508 (via 3rd party) and prior-use certificate of FMEDA data for safety installations

| Accuracy | Up to ±0.075% of span |

| Warranty | Up to 5-yr limited Warranty |

| Rangedown | Up to 150:1 |

| Max. Operating Pressure | Up to 300 psi (20,68 bar) |

| Process Temperature Range | Based on fill fluid - Maximum 401°F (205°C), Minimum -157°F (-105°C) |

| Communication Protocol | 4-20 mA HART®, WirelessHART®, FOUNDATION™ Fieldbus, PROFIBUS®, 1-5 V Low Power HART® |

| Seal System Type | Direct Mount, Tuned-System |

| Transmitter Connection | Welded-Repairable |

| Process Connection | Flanged: ANSI/ASME, EN/DIN, JIS |

| Process Wetted Material | 316L SST, Alloy C-276, Tantalum |

| Diagnostics | Basic Diagnostics, Power Advisory Diagnostics |

| Certifications/Approvals | SIL 2/3 certified to IEC 61508 by an independent 3rd party, NACE®, hazardous location, see full specs for complete list of certifications |