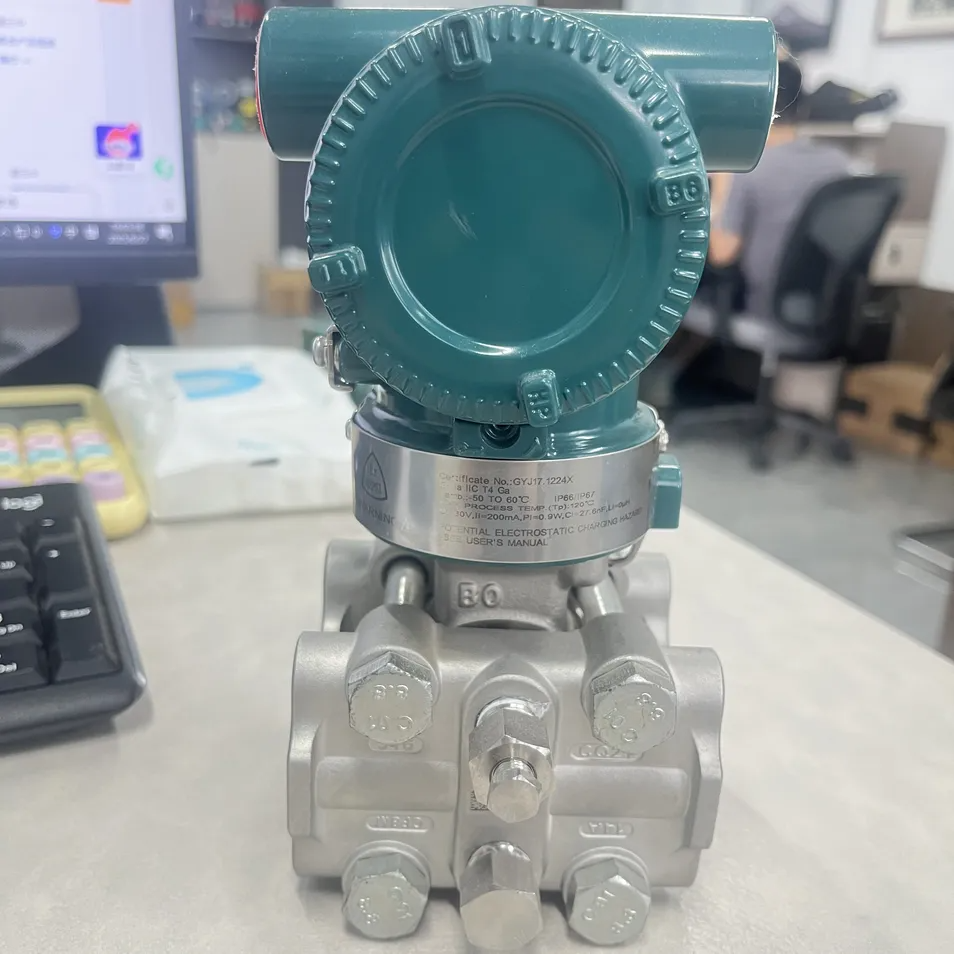

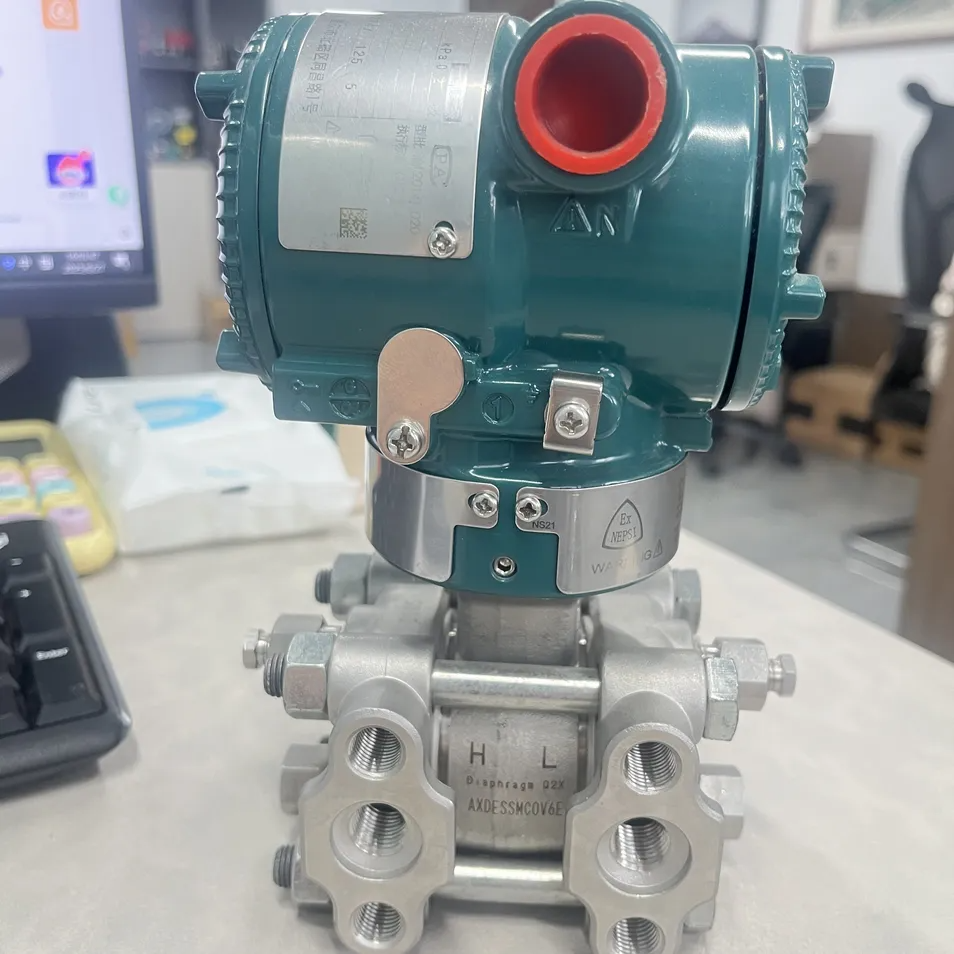

Yokogawa EJA120E differential pressure transmitter

Yokogawa Eja120e Draft Range Differential Pressure Transmitter

Product Description

YOKOGAWA Differential Pressure Transmitter EJA120E

The high performance draft range diff erential pressure

transmitter EJA120E features single crystal silicon resonant sensor and is suitable to measure liquid, gas, or steam fl ow as well as liquid level, density and pressure. EJA120E outputs a 4 to 20 mA DC signal corresponding to the measured diff erential pressure.

Other key features include quick response, remote set-up using communications and self-diagnostics.

FOUNDATION Fieldbus, PROFIBUS PA and 1 to 5 V DC with HART (Low Power) protocol types are also available. EJA-E series models in their standard configuration, with the exception of the Fieldbus, PROFIBUS and Low Power types, are certified as complying with SIL 2 for safety requirement.

transmitter EJA120E features single crystal silicon resonant sensor and is suitable to measure liquid, gas, or steam fl ow as well as liquid level, density and pressure. EJA120E outputs a 4 to 20 mA DC signal corresponding to the measured diff erential pressure.

Other key features include quick response, remote set-up using communications and self-diagnostics.

FOUNDATION Fieldbus, PROFIBUS PA and 1 to 5 V DC with HART (Low Power) protocol types are also available. EJA-E series models in their standard configuration, with the exception of the Fieldbus, PROFIBUS and Low Power types, are certified as complying with SIL 2 for safety requirement.

Applications

Flow Measurement: Suitable for measuring the flow rate of liquids, gases, and steam. By measuring the differential pressure across flow elements such as orifice plates or venturi tubes, the flow rate can be calculated according to relevant formulas.

Level Measurement: According to the hydrostatic principle, the differential pressure is proportional to the liquid level height. Therefore, it can be used to measure the liquid level in tanks by measuring the differential pressure.

Density Measurement: In some processes, by measuring the differential pressure and pressure of the medium, and combining with relevant calculation formulas, the density of liquids or gases can be calculated. It is widely used in chemical, power, water and wastewater treatment, bio - fuel and other industries.

Level Measurement: According to the hydrostatic principle, the differential pressure is proportional to the liquid level height. Therefore, it can be used to measure the liquid level in tanks by measuring the differential pressure.

Density Measurement: In some processes, by measuring the differential pressure and pressure of the medium, and combining with relevant calculation formulas, the density of liquids or gases can be calculated. It is widely used in chemical, power, water and wastewater treatment, bio - fuel and other industries.

Benefits

High - precision Measurement: With an accuracy of up to ±0.2% of span (0.09% with the / hac option), it can provide accurate differential pressure measurement results, which is crucial for ensuring the stable operation of the process and product quality control

Fast Response: The 150 - ms response time allows the transmitter to quickly respond to pressure changes, enabling timely monitoring and control of the process, and is suitable for applications that require rapid response

Good Stability: The DPharp digital sensor and a series of design features ensure the long - term stable operation of the transmitter, with a stability of ±0.3% per year, which can extend the calibration interval and reduce maintenance costs

Fast Response: The 150 - ms response time allows the transmitter to quickly respond to pressure changes, enabling timely monitoring and control of the process, and is suitable for applications that require rapid response

Good Stability: The DPharp digital sensor and a series of design features ensure the long - term stable operation of the transmitter, with a stability of ±0.3% per year, which can extend the calibration interval and reduce maintenance costs

Powerful Communication: Supporting a variety of communication protocols, it can be seamlessly connected to different control systems, facilitating remote monitoring, parameter setting and diagnosis, and improving the degree of automation of the entire system

Specification

Item | valve |

Type | Differential pressure transmitter |

Measurement Range | 1 mbar to 10 mbar |

Accuracy | ±0.2% of span, 0.09% available with /hac option |

Stability | ±0.3% per 1 year |

Response Time | 150 ms |

Output Signal | Two - conductor 4 - 20 mA DC with digital communication, linear or square root output |

Communication Protocol | HART 5/7, 1 - 5 V DC HART 7 (low - power), FOUNDATION Fieldbus, PROFIBUS PA, BRAIN |

Power Supply | 10.5 - 42V DC (general and explosion - proof types); 10.5 - 32V DC with arrester (option code /A); 10.5 - 30V DC (intrinsic safety, n - type, non - flammable type); 9 - 28V DC for 1 - 5V HART (ordinary and explosion - proof types) |

Load | 250 - 600Ω for 4 - 20 mA HART/BRAIN; ≥1MΩ for 1 - 5V HART (three - wire connection, cable length may affect output signal accuracy) |

Protection Class | IP68 (optional, recommended to use sealed cable gland) |

Certification | EXIDA and TÜV SIL 2/3 certified; ATEX, FM, CA, IECEx; Marine: LR, ABS, BV and DNV - GL |

Local Indicator | Optional, can display variables such as DP, SP, capsule temperature, alarm codes, and a bar graph |

Self - diagnosis Function | 40 self - diagnostic checks, including patented back - check technology |

Mounting | Traditional - mount |

Wetted Parts Material | coated 316L stainless steel flange gasket (typical), and other materials are optional according to requirements |